| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : XYMJ

Model Number : Customized

Certification : ISO 9001:2018

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000 kilograms per month

Delivery Time : 7-15

Packaging Details : Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton

Size : Customer's Request

Raw material : 100% Virgin Tungsten carbide

Free Sample : 1-2 pcs available

surface : polished or blank

Specification : Customized

Color : Silver Grey

Wear Resistance Tungsten Carbide Valve Seat Used In Oil Drilling Industry

Tungsten carbide ball seat and valve seat

We can supply various grades for cemented carbide balls/pellets according to customer's requests.

The surface finish, tolerance class and tolerances of dimensions have respectively reached the standards of the machine industry.

The tungsten carbide valve seat is always using with carbide balls.

Features

1. Made by 100% original raw materials

2. Various grades: WC 94%,Co 6%; WC 92%, Co 8%; WCNi and so on

3. Hip sintered, high hardness, high wear resistance

4. High strength, good temperature resistance and corrosion resistance

5. Precise control on dimension

6. OEM Customized

7. Accept trial small order and provide professional technical support

Application

1. Sealing of valves of oil pumps in petroleum industry's sand containing wells

2. Viscous oil wells, sea oil wells

3. High pressure sulfur resistant oil wells

4. Suck Rod Oil Well Pump

5. Vertical well drilling tools

6. Self-activated oscillating-rotating impact drilling tools

7. Compatible cemented carbide valve seats

Grade List

| Grade | WC% | CO% | Hardness (HRA) | Desnity (G/M³) | T.R.S (Mpa) | Metallographic analysis | Application |

| YG6 | 94% | 6% | 91 | 14.6-15.0 | 1700 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG6X | 94% | 6% | 92 | 14.6-15.0 | 1450 | A02B02C02 | Widely used in all kinds of hardware industry, valve, bearing, die casting , punching, grinding measurement. |

| YG8 | 92% | 8% | 89 | 14.4-14.8 | 1800 | A02B02C02 | Widely used in valves,bearing, die casting , punching, grinding measurement,hardness tester, petroleum, chemical industry, aeronautics and astronautics. |

Grade and applicaton for valve seat

| Grade | Co (wt%) | Density (g/cm³) | Hardness(HRA) | TRS (≥N/mm²) | Application |

| XC100 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2000 | Wear-resistant |

| XC101 | 5.8-6.2 | 14.6-15.0 | 91.5-92.5 | 2500 | |

| XC200 | 7.8-8.2 | 14.5-14.9 | 91.0-92.0 | 2100 | |

| XC201 | 7.8-8.2 | 13.5-14.9 | 91.0-92.0 | 2800 | |

| XC300 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 2600 | |

| XC301 | 9.8-10.3 | 14.2-14.6 | 90.5-91.5 | 3200 | |

| Grade | Ni (wt%) | Density (g/cm³) | Hardness (HRA) | TRS (≥N/mm²) | Application |

| XN100 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 1800 | Corrosion-resistant |

| XN101 | 6.5-7.5 | 14.5-14.8 | 88.5-91.0 | 2200 | |

| XN300 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2100 | |

| XN301 | 10.0-11.0 | 14.2-14.6 | 86.5-89.5 | 2400 |

| Seats dimension (mm) | ||

| D | d | H |

| 19.48 | 11.68 | 12.7 |

| 22.66 | 13.97 | 12.7 |

| 28.22 | 17.02 | 12.7 |

| 33.81 | 20.96 | 12.7 |

| 36.09 | 24.38 | 12.7 |

| 41.43 | 26.92 | 12.7 |

| 48.79 | 33.27 | 12.7 |

| 74.93 | 43.18 | 19.05 |

| Ball dimension (mm) | ||

| D±1.27(mm) | ||

| 15.88 | ||

| 19.05 | ||

| 23.83 | ||

| 28.58 | ||

| 31.75 | ||

| 34.93 | ||

| 42.88 | ||

| 57.15 |

Specifications of Valve Ball & Valve Seat for API Sucker Rod Pump

Model/Item | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

| Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

| Seat-ID ± 0.050 (± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

| Seat-OD +0.000/-0.005 (+0.00/-0.13) | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

| Seat-H +0.020/-0.010 (+0.51/-0.25) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 12.70 (0.500in) | 19.05 (0.750in) |

| 10600 | 12500 | 15000 | 17500 | 20000 | 22500 | 25000 | 37500 | ||

| D (customized) | Inch | 0.625 | 0.725 | 0.938 | 1.125 | 1.250 | 1.375 | 1.688 | 2.250 |

| mm | 15.88 | 19.05 | 23.83 | 28.58 | 31.75 | 34.93 | 42.88 | 57.15 | |

| H -0.020/-0.010 (+0.51/0.25) | Inch | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.500 | 0.750 |

| mm | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 12.70 | 19.05 | |

| FZ +0.000/-0.031 (+0.00/-0.78) | Inch | 0.767 | 0.892 | 1.11 | 1.331 | 1.421 | 1.631 | 1.921 | 2.950 |

| mm | 19.48 | 22.66 | 28.22 | 33.81 | 36.09 | 41.43 | 48.79 | 74.93 | |

| OD +0.000/-0.005 (-0.00/-0.13) | Inch | 0.793 | 0.918 | 1.168 | 1.388 | 1.478 | 1.720 | 2.010 | 3.072 |

| mm | 20.14 | 23.32 | 29.67 | 35.26 | 37.54 | 43.69 | 51.05 | 78.03 | |

| ID +/-0.050 (+/-1.27) | Inch | 0.460 | 0.550 | 0.670 | 0.825 | 0.960 | 1.060 | 1.310 | 1.700/1.800 |

| mm | 11.68 | 13.97 | 17.02 | 20.96 | 24.38 | 26.92 | 33.27 | 43.18/47.75 | |

Dimensional Symbol | V11-106 | V11-125 | V11-150 | V11-175 | V11-200 | V11-225 | V11-250 | V11-375 |

Ball-D +0.020/-0.010 (+0.51/-0.25) | 15.88 (0.625in) | 19.05 (0.75in) | 23.83 (0.938in) | 28.58 (1.125in) | 31.75 (1.25in) | 34.93 (1.375in) | 42.88 (1.688in) | 57.15 (2.25in) |

Seat-ID ± 0.050 ( ± 1.27) | 11.68 (0.46in) | 13.97 (0.55in) | 17.02 (0.67in) | 20.96 (0.825in) | 24.38 (0.96in) | 26.92 (1.06in) | 33.27 (1.31in) | 43.18 (1.7in) |

Seat-OD +0.000/-0.005 +0.00/-0.13 | 20.14 (0.793in) | 23.32 (0.918in) | 29.67 (1.168in) | 35.26 (1.388in) | 37.54 (1.478in) | 43.69 (1.72in) | 51.05 (2.01in) | 78.03 (3.072in) |

Seat-H +0.020/-0.010 (+0.51/-0.25) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.500 (12.70in) | 0.750 (19.05in) |

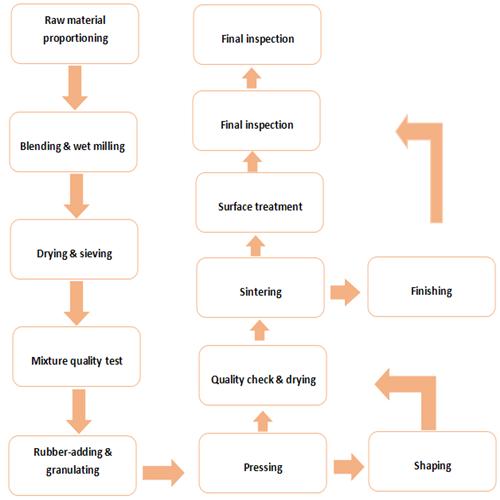

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.

|

|

Silver Grey Tungsten Carbide Valve Seats High Hardness For Oil Drilling Industry Images |