| Sign In | Join Free | My chinacsw.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinacsw.com |

|

Brand Name : XYMJ

Model Number : Customized

Certification : ISO 9001:2015

Place of Origin : China

MOQ : Negotiable

Price : Negotiable

Payment Terms : L/C, D/A, D/P, T/T, Western Union, MoneyGram

Supply Ability : 2000 kilograms per month

Delivery Time : 7-15

Packaging Details : Inner packing: wrapped by bubble bag,foam. Outer packing: standard export carton

Material : WC+Co

Application : Manufacturing Plant, Energy , Mining

Precision : High Precision

Package : Standerd Export Carton

Product Name : Tungsten Carbide Shaf Sleeves

Sample Order : Accepted

High Strength Wear Resistant Carbide Bushing, Carbide Shaft Sleeve

Details of Tungsten Carbide Bush for Reference

1. Material: high virgin raw material with sub-micron and average grain size.

2. Grades: various for choice: YG6, YG8, YN6, YN8 and so on.

3. Physical performance: high hardness and impact toughness, very good mechanical & chemical stability.

4. Standard and non-standard sizes are available for us.And the grades could be chose as actual application.

Application

1. Tungsten Carbide Bearing Bushings have the characters of high wear resistance, high corrosion resistance and good compressive properties.

2. It's widely used in petrochemical industries and other industries which call for high properties of the bearing bushings or shaft sleeves.

3. Tungsten carbide bush is the basic material among the frictional materials. They are widely use as the basic components for sealing. And the bushings are widely adopted in petrochemical industry due to its excellent performances such as wear ability, anti corrosion.

Grade List

| Grade | ISO Code | Chemical Composition(%) | Physical Mechanical Properties (≥) | Application | ||||

| WC | Co | Density g/cm3 | Hardness(HRA) | T.R.S N/mm2 | ||||

| YG3 | K01 | 97 | 3 | 14.90 | 91.00 | 1180 | Suitable for finishing of cast iron,non-ferrous metals,alloys and non-metallic materials,and semi-finishing vehicles for intermittent cutting. | |

| YG6 | K10 | 94 | 6 | 15.10 | 92.00 | 1420 | Finishing of chilled hard alloy cast iron and heat resistant alloy steel and ordinary cast iron. | |

| YG6X | K20 | 94 | 6 | 15.10 | 91.00 | 1600 | Cast iron, non-ferrous metals and alloys, non-metallic materials, medium to cutting, semi-finishing and finishing. | |

| YG8 | K20-K30 | 92 | 8 | 14.90 | 90.00 | 1600 | Suitable for casting of cast iron, non-ferrous metals and their alloys and non-metallic materials, roughing of sections and rough cutting. | |

| YG10 | K40 | 90 | 10 | 14.70 | 89.00 | 1900 | Suitable for the production of drawing dies, wear parts and stamping parts and cores for hard alloy automatic presses. | |

| YG10X | K40 | 89 | 10 | 14.70 | 89.50 | 2200 | Suitable for small diameter micro drills, end mills, rotary boring tools, etc. | |

| YG15 | K30 | 85 | 15 | 14.70 | 87.00 | 2100 | Forging, perforating and stamping tools for steel bars and steel tubes with high compression ratios and working under large stresses. | |

| YG20 | K30 | 80 | 20 | 13.70 | 85.50 | 2500 | Stamping die, stamping watch parts, musical instrument spring piece. | |

| YG20C | K40 | 80 | 20 | 13.70 | 82.00 | 2200 | punching battery case, toothpaste skin mold, small size steel ball, screw, nut stamping die, hot rolling twist drill bit plate. | |

| YG30 | G60 | 70 | 30 | 12.80 | 82.00 | 2750 | Production of standard parts, bearings, tools and other industries for cold heading, cold punching, cold pressing die. | |

Details Carbide Bushing

| Deimensions of A Type Straight Sleeves (mm) | ||||

| Type No. | D | d | H | C |

| XA1 | 14.5-20 | 12.16 | 6.0-10.0 | 1.3 |

| XA2 | 12.5 | 3.5-7.0 | 12.7 | 4.5 |

| XA3 | 21-60 | 15-50 | 51 | 3 |

| XA4 | 75-130 | 60-115 | 55-100 | 6 |

| XA5 | 140-300 | 120-200 | 60-150 | 10 |

Product Application Scene

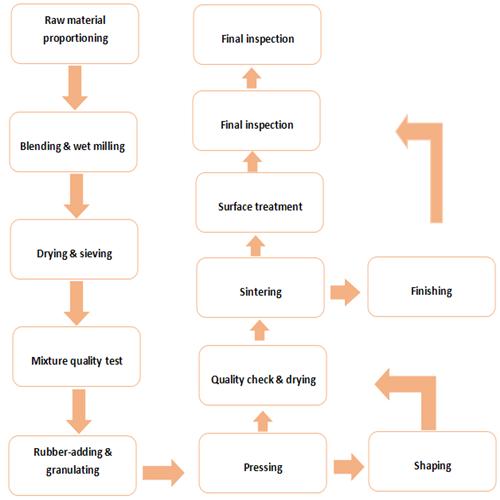

Production Process

FAQ

Q1: How long is your delivery period?

A1: It depends on specific conditions. However, it could be 10 to 15 days on average.

Q2: Do you offer samples?

A2: Yes, we do offer samples. However, buyers need to pay for the freight charge. In addition, whether samples are free or not depends on the quantity you buy.

Q3: How do you pack the products?

A3: In general, we use wood, plastic or carton boxes. We also put some soft materials inside to prevent possible damage on products.

Q4: How much advance payment do I need to make?

A4: If the products you buy are in stock, you need to make full payment; if the products are out of stock, you need to make about 50 percent of full payment and then we will start the production process. However, you still need to pay the rest of charges before we deliver the products.

Q5: What kinds of payment do you accept?

A5: In addition to the patterns of payment shown above, you can discuss with us about in which way you would like to pay.

Please contact us if you have any other questions.

|

|

High Strength Hard Steel Bushings Good Mechanical Chemical Stability Images |